Revolutionizing Packaging Efficiency: The Technological Advancements in Box Pressing Machinery

In the competitive landscape of the packaging industry, efficiency and innovation are key drivers of success. Box pressing machinery, a critical component in the production of cardboard and corrugated boxes, has seen significant technological advancements that have transformed the way businesses approach packaging. This article explores the cutting-edge technologies that are shaping the future of box pressing machinery and, by extension, the packaging industry.

Advanced Automation and Control Systems

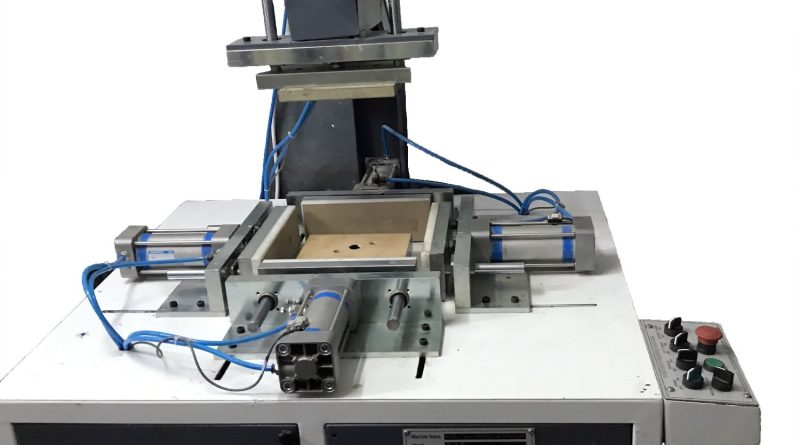

One of the most significant technological advancements in box pressing machinery is the integration of advanced automation and control systems. These systems enable precise control over the pressing process, ensuring uniformity and consistency in box production. With programmable logic controllers (PLC) and computer numerical control (CNC) technology, operators can easily adjust parameters such as pressure, duration, and temperature, tailoring the pressing process to specific box requirements.

Enhanced Material Efficiency

Modern box pressing machines are designed with material efficiency in mind. Through the use of sophisticated sensors and software algorithms, these machines can optimize material usage, reducing waste and minimizing the environmental impact of packaging production. This not only supports sustainability initiatives but also contributes to cost savings for manufacturers.

IoT and Connectivity

The Internet of Things (IoT) has found its way into box pressing machinery, offering unprecedented levels of connectivity and data analysis. IoT-enabled machines can collect and analyze data in real-time, providing insights into machine performance, maintenance needs, and production trends. This connectivity allows for predictive maintenance, reducing downtime and ensuring continuous operation.

High-Speed Production Capabilities

Speed is crucial in the packaging industry, and modern box pressing machinery delivers on this front. With high-speed production capabilities, these machines can meet the demands of even the most time-sensitive projects. The combination of speed and precision ensures that manufacturers can produce high-quality boxes at a pace that keeps up with market demands.

Customization and Flexibility

As the market for packaging becomes increasingly diverse, the need for customization and flexibility in box production has never been higher. Technological advancements in box pressing machinery have led to the development of machines that can handle a wide range of sizes, shapes, and materials. This flexibility allows manufacturers to cater to the unique needs of their clients, providing custom packaging solutions that stand out in the marketplace.