Box Pressing Machines: Streamlining the Packaging Process for Optimal Results

Introduction: In the fast-paced world of product manufacturing and distribution, effective packaging is crucial. Box pressing machines play an essential role in ensuring that packages are not only aesthetically pleasing but also sturdy and functional. This article provides an in-depth look at box pressing machines, explaining their purpose, functionality, and the benefits they bring to the packaging industry.

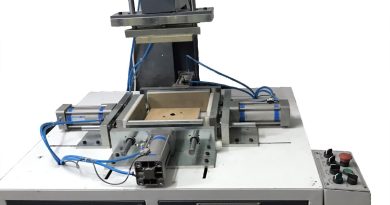

What is a Box Pressing Machine? A box pressing machine is a specialized device used in the packaging industry to ensure that boxes are properly formed and reinforced. After a box is assembled, it may still have weak joints or misaligned edges. A box pressing machine applies uniform pressure across the surface of the box to enhance adhesion in the joints and ensure the box maintains its intended shape and structural integrity.

Operational Features:

- Uniform Pressure Application: Box pressing machines use hydraulic or pneumatic systems to apply consistent pressure across all box joints, securing the adhesive bonds and smoothing out any irregularities.

- Adjustable Settings: Most machines feature adjustable settings to handle various box sizes and materials, making them versatile for different packaging needs.

- Automation: Many box pressing machines are fully automated, which helps to streamline the packaging process, reducing labor costs and increasing production speed.

Benefits of Using Box Pressing Machines:

- Enhanced Box Quality: By pressing the boxes, these machines ensure that each package is robust and durable, reducing the risk of damage during shipping or storage.

- Increased Production Efficiency: Automating the box pressing process allows for faster production times and helps maintain a consistent output rate.

- Improved Aesthetics: Pressed boxes are more visually appealing, which is important for consumer-facing products. A well-formed box enhances the overall presentation and can improve customer satisfaction.

- Cost-Effectiveness: With increased efficiency and reduced need for manual labor, box pressing machines help lower production costs over time.

Applications Across Industries: Box pressing machines are used in various sectors where packaging quality is critical:

- Electronics: Ensuring that electronic devices are securely packaged to prevent damage.

- Food and Beverage: Stabilizing packaging for transport and display.

- Pharmaceuticals: Providing secure and tamper-evident packaging to ensure product safety.

- Cosmetics and Personal Care: Enhancing product presentation through flawless packaging.

Conclusion: Box pressing machines are invaluable assets in the packaging process, providing numerous benefits across various industries. They enhance the durability, appearance, and overall quality of packaging, contributing to more efficient production lines and better consumer experiences. As technology advances, these machines continue to evolve, offering even greater precision and efficiency to meet the growing demands of the packaging industry.