Box Pressing Technology: Elevating Packaging Efficiency and Eco-Friendliness

The advent of box pressing technology has marked a transformative era in the packaging industry, marrying efficiency with environmental responsibility. This concise article explores the pivotal advantages of box pressing technology and its profound implications for the future of packaging.

Streamlining Production

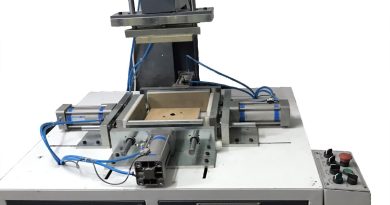

Box pressing technology stands out for its ability to streamline the entire packaging process. By automating tasks such as cutting, folding, and sealing, these machines significantly reduce production times and enhance throughput. This automation translates to a remarkable increase in efficiency, allowing for the rapid production of high-quality cardboard boxes. The precision and consistency offered by these machines minimize waste and optimize material use, contributing to both operational efficiency and cost reduction.

Fostering Environmental Stewardship

A cornerstone of box pressing technology is its contribution to sustainable packaging solutions. By facilitating the integration of recycled materials into new products, box pressing machines underscore the packaging industry’s shift towards greener practices. This technology not only reduces the reliance on virgin materials but also minimizes the environmental impact of packaging waste. The energy-efficient operation of these machines further solidifies their role in promoting a more sustainable packaging industry.

Advancing with Innovation

The integration of cutting-edge technology in box pressing machines, including sophisticated control systems and real-time monitoring, elevates packaging quality to new heights. These advancements ensure unparalleled precision in box production, reducing errors and enhancing product reliability. Additionally, the adaptability of box pressing machines to various box designs and specifications makes them a versatile solution for a wide range of packaging needs, from small-scale boutique items to large-scale industrial goods.