Box Pressing Machines: Revolutionizing the Packaging Industry

The packaging industry is undergoing continuous evolution, driven by rapidly advancing technologies and escalating consumer expectations. Within this dynamic sector, box pressing machines emerge as a revolutionary innovation, merging efficiency, sustainability, and quality to fundamentally transform packaging production.

Efficiency and Speed

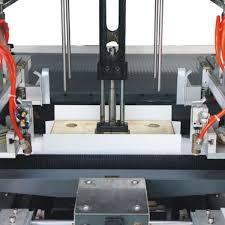

Box pressing machines automate the cardboard box production process, dramatically increasing production speed and efficiency compared to manual processes. These machines integrate cutting, folding, and gluing operations to produce high-quality boxes in seconds. This speed is crucial during peak demand periods, enabling businesses to respond promptly to customer needs and adapt quickly to market dynamics.

Environmental Sustainability

Box pressing machines play a significant role in promoting environmental sustainability. Their compatibility with recycled materials reduces waste and optimizes material usage, thus diminishing the environmental impact of businesses. These features appeal to the growing environmental consciousness among consumers and strengthen brands’ green identities.

Quality and Consistency

The consistency and high-quality standards provided by box pressing machines make a noticeable difference in all aspects of packaging. Machines ensure each box is uniform in size and shape, allowing for the safe and aesthetic packaging of products. This increases end-user satisfaction and reinforces brand loyalty.

Conclusion

Box pressing machines have become indispensable tools for businesses striving for excellence in the packaging industry. Offering speed, efficiency, sustainability, and superior quality, these machines are key factors in keeping businesses competitive. The future of packaging will be shaped by the innovation and adoption of box pressing technology, leading the industry towards a greener, more efficient, and innovative path.